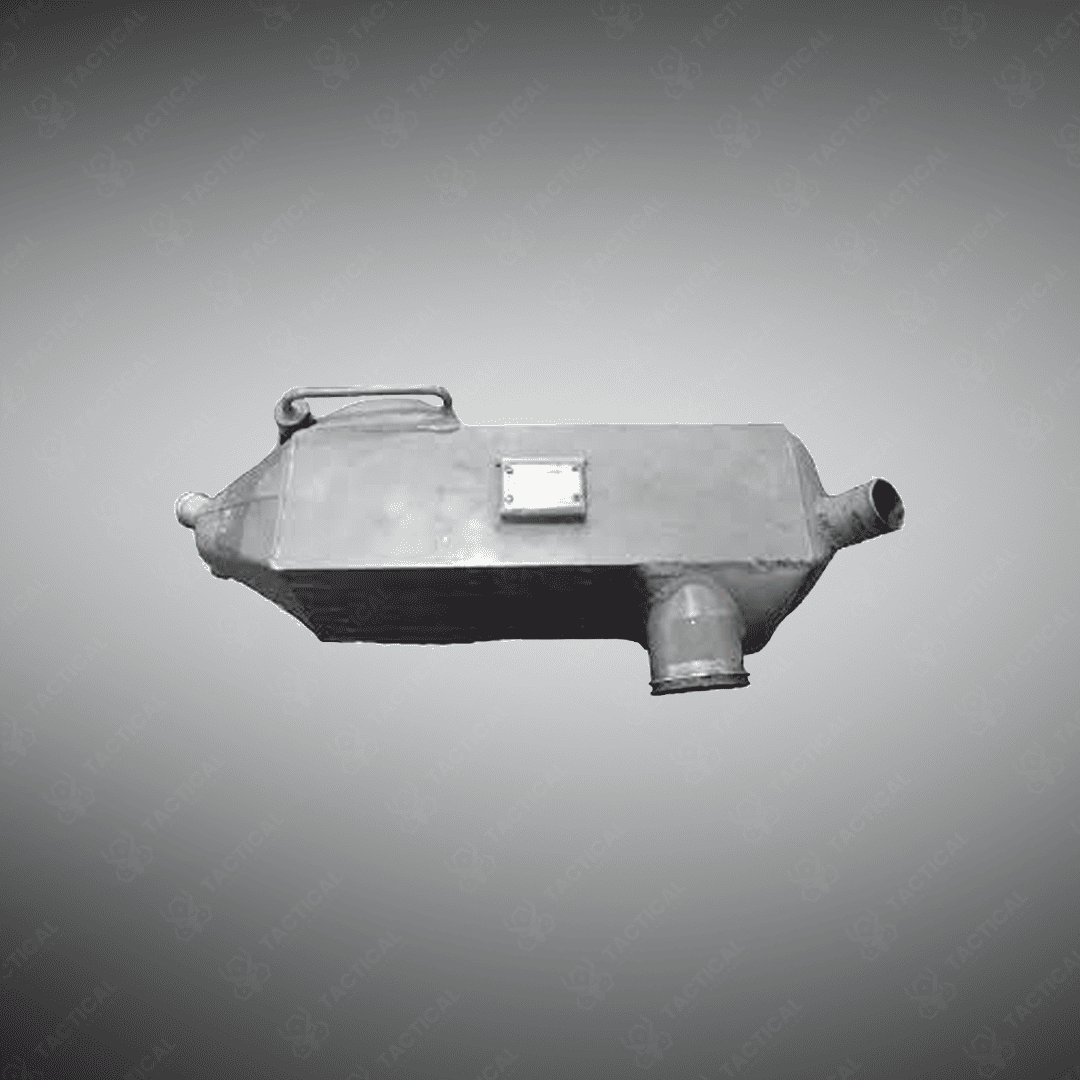

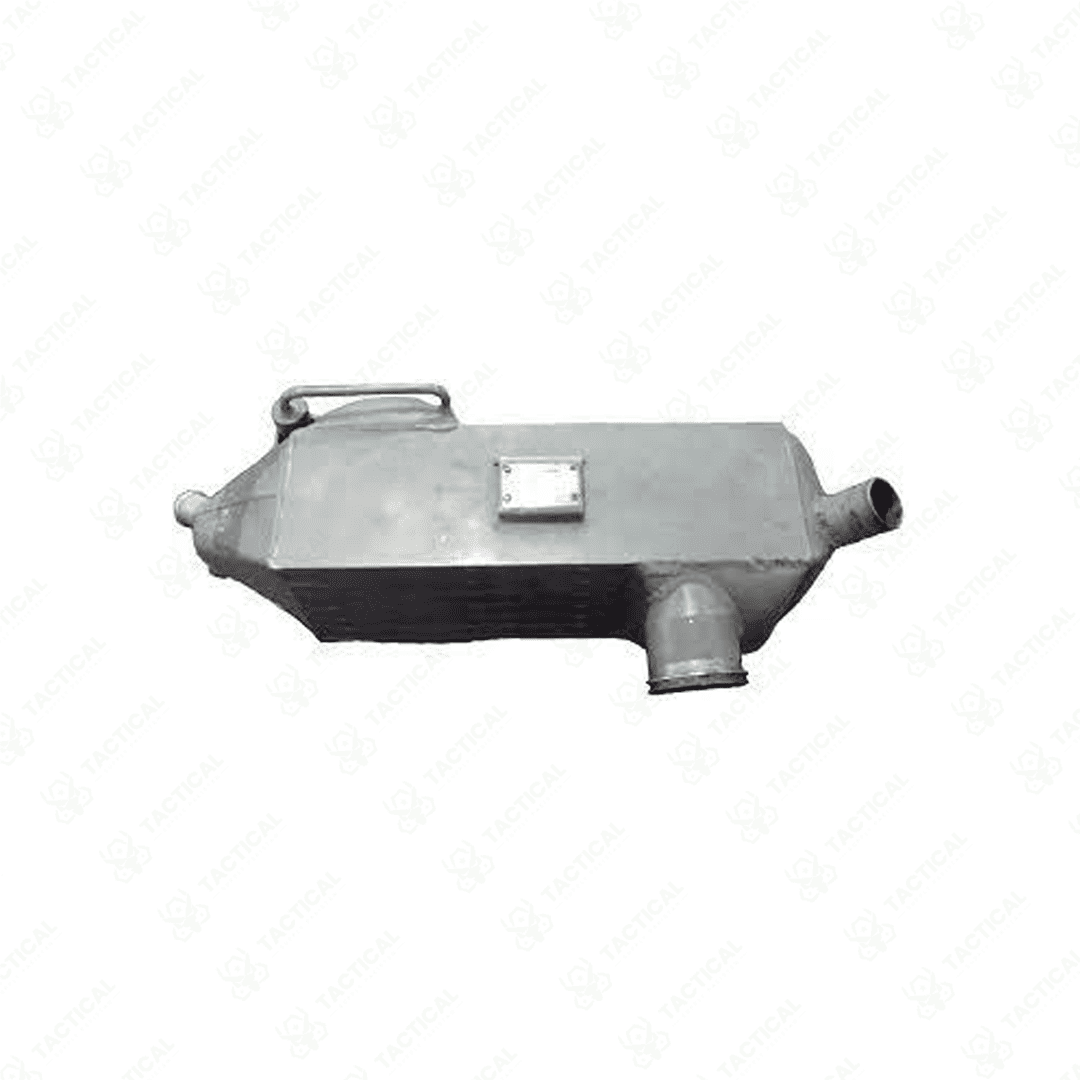

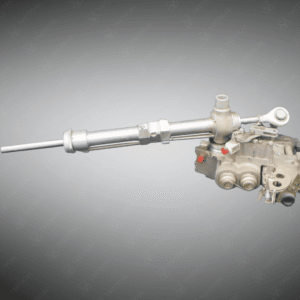

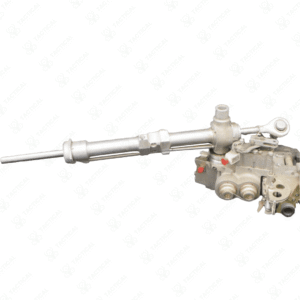

Heat Exchanger

High-performance heat exchanger for thermal regulation in the F-16’s Environmental Control System (ECS), ensuring system stability during critical operations.

Key Features:

✔️ Manages heat from engine oil and hydraulic systems

✔️ Built with Inconel and stainless steel for durability

✔️ Finned-tube design for efficient heat transfer

✔️ Lightweight and compact for easy airframe integration

✔️ Supports avionics, radar, and ECS temperature control

✔️ Compliant with NATO and U.S. Air Force standards

Heat Exchanger

The Heat Exchanger for F-16 Aircraft is a critical component within the aircraft’s Environmental Control System (ECS), designed to manage and dissipate heat generated by various onboard systems. Constructed from high-strength, corrosion-resistant materials such as Inconel and stainless steel, this unit ensures durability and performance under extreme operational conditions.

This heat exchanger operates by transferring excess heat from engine oil and hydraulic fluids to the aircraft’s fuel or ambient air, thereby maintaining optimal temperatures for essential systems. Its design incorporates a series of finned tubes and baffles to maximize surface area and enhance heat transfer efficiency. The unit’s compact and lightweight construction allows for seamless integration into the F-16’s airframe without compromising structural integrity or performance.

In the F-16, the exchanger plays a pivotal role in maintaining the thermal balance of the aircraft, ensuring that critical components such as avionics, radar systems, and flight control electronics operate within their designated temperature ranges. By effectively managing heat loads, it contributes to the aircraft’s overall reliability and mission readiness, especially during high-performance maneuvers and extended flight operations.

Supplied by Tactical Supply Pakistan, this heat exchanger meets stringent military specifications and undergoes rigorous quality assurance processes to ensure compliance with NATO and U.S. Air Force standards. Each unit is tested for thermal performance, pressure resistance, and structural integrity to guarantee optimal functionality in demanding environments

How often should the heat exchanger be inspected in service?

It is typically inspected during major maintenance intervals or when abnormal temperature readings are noted. Preventive checks every 400–600 flight hours are recommended, depending on operational intensity and environmental exposure.

- Fast Shipping: We partner with reliable delivery services to make sure your order gets to you quickly. We work hard to ensure every package arrives safely and on time.

- Quick Processing: Your order is processed and prepared for shipping within 24 to 48 hours. This allows us to send it out to you as fast as possible after your payment is confirmed.

- Tracking: Once your order is on its way, we will provide you with a tracking number. You can use this number to easily follow your package's journey and know exactly when it will arrive.

- Nationwide Delivery: We offer delivery to all locations across Pakistan, including major cities and remote areas. No matter where you are, we can get your order to you.

At Tactical Supply Pakistan, our relationship with you doesn't end after a sale. We are dedicated to making the long-term performance and reliability of our high-quality tactical and supplied equipment. Our commitment is to provide you with seamless support and peace of mind.

- Free Installation: We'll set up your new equipment for you, so it's ready to go. You can focus on your work while our engineers handle as per the guidelines for manufacturer.

- Maintenance: We offer quick replacements where necessary, to keep your gear in top condition. Our team will make sure your equipment is always ready when you need it.

- Customer Support: We're always here to help. Our support team is available to answer your questions and assist you long after you've made a purchase.

- Planned Preventative Maintenance: Our service includes preventative maintenance to keep your equipment in peak condition and prevent future issues.

HAVE QUESTIONS?

Fill out the form, and our team will respond promptly to assist with your product inquiries or order support.