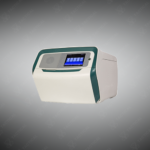

Centrifugal Heat-Sealing Machine

Integrated system for simultaneous SNP chip centrifugation and heat sealing, ensuring precise and contamination-free reaction chambers.

Key Features:

✔️ Dual Function Operation – Centrifugation and heat sealing run simultaneously

✔️ Multi-Chip Capability – Heat seal up to four chips at once

✔️ Precise Temperature Control – Digital PID thermostats for accurate heating

✔️ Large Touchscreen Interface – Easy adjustment and monitoring of settings

✔️ Fully Enclosed Design – Ensures safe and reliable operation

✔️ Isolated reaction chambers maintain sample integrity

✔️ Optimized for SNP Chips – Ideal for post-injection chip sealing

✔️ Compact, Lab-Ready Build – Integrates seamlessly into molecular diagnostics workflows

Centrifugal Heat-Sealing Machine

The Centrifugal Heat-Sealing Machine integrates chip centrifugation and heat-sealing operations in a single unit allowing simultaneous function without process interference. This system processes microfluidic chips measuring 75mm × 25mm × 2.00mm with throughput capacity of 250 chips per hour. The unit accommodates 2 or 4 microfluidic chips per cycle with heat sealing completing on four chips simultaneously. Temperature regulation spans 150°C to 180°C with ±1°C precision controlled through digital PID thermostats. The centrifuge operates at 8000rpm with single centrifugation cycles completing in 1 minute and blocking time ranging 1 to 99 seconds.

The machine measures 470mm × 345mm × 400mm weighing 45kg with a touchscreen interface for parameter adjustment. Construction includes a fully enclosed shell housing separate heat sealing and centrifugal modules alongside the control unit. The isolation design prevents cross-contamination by creating independent reaction chambers within SNP chips after injection. This barrier eliminates inter-sample interference during genetic analysis workflows.

Forensic laboratories deploy the Centrifugal Heat-Sealing Machine for processing SNP chips in criminal identification cases requiring contamination-free sample handling. Military biometric units use this equipment for sealing genotyping chips in personnel identification programs. Naval medical facilities install the system for processing genetic screening chips aboard vessels conducting biosurveillance operations. Airforce biodefense labs operate the machine for sealing pathogen detection chips in rapid response scenarios. Clinical genetics centers utilize the platform for patient sample chip preparation in diagnostic testing protocols.

Tactical Supply Pakistan delivers integrated chip processing systems that combine centrifugation and sealing operations eliminating manual transfer steps between separate instruments. The company provides equipment supporting contamination-controlled workflows in molecular diagnostic laboratories.

Can the machine process chips from different manufacturers?

The system accommodates standard 75mm × 25mm microfluidic chips, which covers most commercial SNP chip formats used in genetic testing applications.

- Fast Shipping: We partner with reliable delivery services to make sure your order gets to you quickly. We work hard to ensure every package arrives safely and on time.

- Quick Processing: Your order is processed and prepared for shipping within 24 to 48 hours. This allows us to send it out to you as fast as possible after your payment is confirmed.

- Tracking: Once your order is on its way, we will provide you with a tracking number. You can use this number to easily follow your package's journey and know exactly when it will arrive.

- Nationwide Delivery: We offer delivery to all locations across Pakistan, including major cities and remote areas. No matter where you are, we can get your order to you.

At Tactical Supply Pakistan, our relationship with you doesn't end after a sale. We are dedicated to making the long-term performance and reliability of our high-quality tactical and supplied equipment. Our commitment is to provide you with seamless support and peace of mind.

- Free Installation: We'll set up your new equipment for you, so it's ready to go. You can focus on your work while our engineers handle as per the guidelines for manufacturer.

- Maintenance: We offer quick replacements where necessary, to keep your gear in top condition. Our team will make sure your equipment is always ready when you need it.

- Customer Support: We're always here to help. Our support team is available to answer your questions and assist you long after you've made a purchase.

- Planned Preventative Maintenance: Our service includes preventative maintenance to keep your equipment in peak condition and prevent future issues.

HAVE QUESTIONS?

Fill out the form, and our team will respond promptly to assist with your product inquiries or order support.