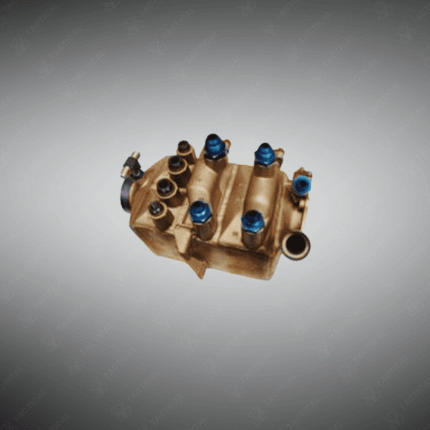

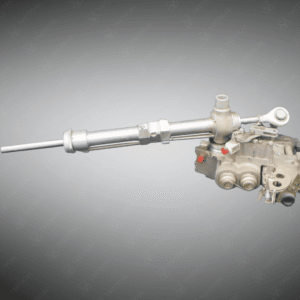

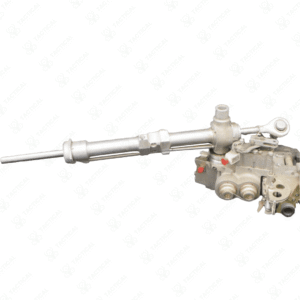

Shock Absorber

Robust hydraulic-pneumatic shock absorber for F-16 landing gear, built to handle extreme vertical loads during landing and taxiing while reducing airframe stress and enhancing ground stability.

Key Features:

✔️ Nitrogen-charged hydraulic-pneumatic system

✔️ High-strength alloy body with corrosion-resistant finish

✔️ Responsive piston mechanism for adaptable load dampening

✔️ Temperature-resistant seals to prevent fluid leakage

✔️ Modular structure for simplified maintenance and replacement

✔️ Reduces bounce, vibration, and structural fatigue

Shock Absorber

The Shock Absorber used in F-16 aircraft is built for high-performance load dampening during landing and taxiing. Engineered with a hydraulic-pneumatic configuration, it includes a nitrogen-charged chamber and precision-sealed fluid reservoir. The outer housing is constructed from high-strength alloys to withstand vertical impact forces while maintaining weight efficiency. Internal piston mechanisms allow dynamic responsiveness to both light and heavy ground contact.

This absorber offers consistent stroke compression and rebound under varying loads, making it adaptable to both training sorties and high-weight tactical landings. It is treated with corrosion-resistant coatings and features temperature-tolerant seals that prevent fluid leakage even under rapid descent cycles. Its modular design supports ease of replacement during maintenance without compromising structural integrity.

The Shock Absorber is installed on the main and nose landing gears of the F-16, where it functions to absorb vertical loads during takeoff and landing. It protects the airframe from sudden impact stresses and reduces fatigue on adjoining components. By minimizing vibration and bounce during ground roll, it contributes to a stable aircraft trajectory during high-speed landings.

Parts like this are mission-critical and sourced by Tactical Supply Pakistan, a brand recognized for delivering components that meet the highest operational and endurance standards required by the F-16 fleet worldwide.

How often should a shock absorber be replaced on an F-16?

Replacement depends on usage intensity and inspection reports but is generally recommended after a defined number of hard landings or when damping performance drops below acceptable thresholds.

SECURE & TRACKED SHIPPING

All equipment is packed using reinforced, tamper-resistant materials to prevent damage from impact, moisture, or pressure. Shipments are dispatched via trusted defense-grade logistics networks. Each package is fully traceable, and tracking information is shared with clients immediately after dispatch to ensure secure and visible transit from origin to destination.

TIMELY DELIVERY & LOGISTICS SUPPORT

Orders are processed promptly upon verification.

• Real-time tracking gives complete visibility at every stage.

• Customs documentation and clearances are fully handled.

• Live support is available for rerouting or inquiries.

Our logistics specialists stay in contact throughout delivery, ensuring every product reaches its destination efficiently, securely, and without delays that could affect operational readiness

HAVE QUESTIONS?

Fill out the form, and our team will respond promptly to assist with your product inquiries or order support.